4 Things About Diamonds: Shape, Concentration, Grit And Grade

Diamonds are the hardest naturally-occurring substance on Earth. The key qualities of this material are its high hardness, melting point, and insulation, as well as its resistance to corrosion from chemicals and acids. The tools made from diamonds (diamond tools) are especially effective for processing hard and brittle materials, especially non-metallic materials such as stone, wall and floor tiles, glass, ceramics, concrete, and so forth.

Natural diamonds are most often used for consumer goods, like jewelry, while artificial diamonds are usually used in industrial fields, such as for making diamond tools.

Artificial diamonds are the working part of all diamond tools for cutting, grinding or drilling. We can study it from four aspects: shape, concentration, grits, and grade.

Shape

There are mainly 2 different shapes of diamonds: granular and flat. They are used in different fields.

Granular diamonds are mainly used for cutting and drilling, good granular material should be angular, these edges and corners are the guarantee of cutting effect.

Flat diamonds are mainly used for grinding and polishing because they create a smoother finish without leaving scratches.

Concentration

The content of diamond in diamond tools is expressed by concentration. Different from the concentration that we usually understand. The diamond concentration in diamond tools has its own standard: the concentration of 4.4 carats of diamond in a volume of 1 cubic centimeter is 100%.

The concentration of diamonds is linked to the price, use of the diamond tools. For example, the diamond concentration of a multi-layer segment is different from that of a sandwich segment. The diamond concentration in diamond cutting tools is also different from that in grinding tools.

What is more, the concentration of diamonds is also related to the service life and sharpness of diamond tools. Generally, as the concentration of diamonds increases, the service life of diamond tools will be prolonged, though the sharpness will decrease.

Grits

The size of diamond is divided by grit, from 25/30 to the micro-powder level. The coarser the diamond, the smaller the grit value, and the faster the cutting efficiency. Typically, granite uses diamond with a grit range of 35/40-60/70 while marble uses 60/70-80/100. Micro-powder is generally used in some resin bond diamond tools.

It is the diamond that does the cutting, and grain size is one way of adjusting the sharpness and lifespan of the diamond tools.

1. If the bonding agency is unchanged, a larger diamond can be used to adjust the sharpness.

2. If the life is not concerned and the diamond is unchanged, the wear resistance of the bonding agency can be adjusted to improve the sharpness.

In practice, we typically only mark the diamond grit for diamond grinding/polishing tools and don't print the grits on cutting or drilling tools. Because the diamond grit is one of the most important parameters for grinding/polishing tools.

In fact, the diamond grain size is a range, not a specific number, but sometimes we only use a specific number to simplify it. For example: like 16/20#, we maybe only display 16# on the tools.

The Diamond Grits Used In Different Diamond Tools

| Diamond Tools | Diamond Types | Applied Materials | Diamond Grit Usually Used |

|---|---|---|---|

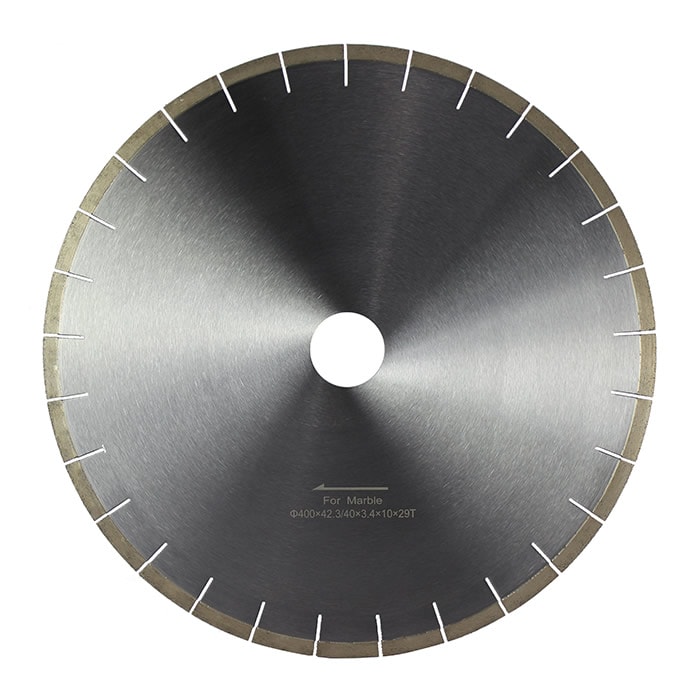

| Diamond Cutting Tools | Granular Type | Granite | 35/40# to 60/70# (for marble blades under 400mm, the grit can be 60/70# to 80/100# to reduce the cutting chips) |

| Marble | |||

| Concrete | |||

| Diamond Grinding Tools | Flat Type | Granite | metal-bonded: 6#, 16#, 36#, 80#, 120#, 180#, 220# resin-bonded: 50#, 100#, 200#, 400#, 800#, 1500#, 3000#, buff |

| Marble | |||

| Concrete | |||

| Diamond Drilling Tools | Granular Type | Granite | 40/45# to 50/60# |

| Marble | 40/45# to 50/60# | ||

| Concrete | 35/40# to 50/60# |

Grade

Different grades of diamonds used for different applications. Usually, diamonds used for cutting and drilling are of better quality than those used for grinding. Because the process of cutting and drilling requires higher quality diamonds than those used for grinding.

If you are searching for a supplier who provides high quality diamond tools, please contact OneStop Diamond Tools. Our diamond tools always use original diamonds, never recycled diamonds. We would be happy to give you the best quotation and other services.