How To Make Diamond Tools?

TABLE OF CONTENTS

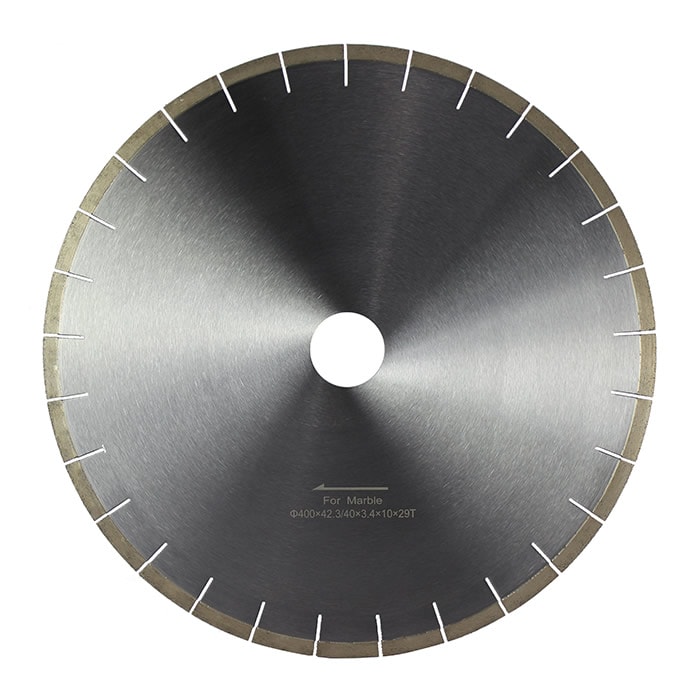

Diamond tools are widely used in the construction industry, for cutting, grinding, and drilling different materials like granite, marble, asphalt, concrete, reinforced concrete and others.

Typical Diamond Tools In Different Applications

| Tool Classification | Typical Diamond Tools |

|---|---|

| Cutting Tools | Diamond Blade, Gang Saw Balde, Diamond Wire Saw, etc. |

| Grinding Tools | Floor Grinding Shoes, Bush Hammers, Diamond Fickert, Diamond Frankfurt, Diamond Cup Wheels, etc. |

| Drilling Tools | Diamond Finger Bit, Diamond Core Drill Bit, etc. |

Although there are many different types of diamond tools, they all feature a similar structure: the part of diamond segments and the part of steel base (core).

The diamond segments are the key functional component that directly contacts the material being processed. The steel core provides the place to fix the diamond segments. It acts as a bridge between the diamond segments and machines, transferring power to the segment and affecting the stability.

The design of the steel core also has an effect on the performance of diamond tools. For example, silent diamond blades use a special steel core with a thin copper layer in the middle to reduce noise when cutting.

This article will provide you with an overview of the typical production process for diamond tools, so that you can feel more confident when making purchase decisions.

For the diamond tools processing, we would like to divide it into two parts: the diamond segment production flow and the other steps remaining.

Diamond Segment Production Flow

1. Powder Preparation

In this step, we weigh diamond particles and different metal powders according to the diamond formulas.

Diamond Segment Powders

Different segments have different diamond formulas. You can check the main elements for different diamond cutting segments through the chart below. The powder preparation is to preparing different powders in a certain proportion, based on the diamond formulas.

| Segment Type | Elements |

|---|---|

| granite cutting segment | Fe, Cu, Ni, Co, Sn, Zn, etc. |

| marble cutting segment | Cu, Co, Sn, Zn, etc. |

| concrete cutting segment | Fe, Cu, Ni, Co, Sn, Zn, WC, etc. |

By the way, I have pasted the function of different metal powders below, in case you are interested.

| Elements | Advantages |

|---|---|

| Fe (Iron) | Iron powder is relatively cheap compared with other metal powders and is generally the main component of the bonds. |

| Cu (Copper) | Copper powder provides adhesion and is sometimes the main component of the bonding agency ( such as marble cutting segment, etc.) |

| Ni (Nickel) | Nickel powder strengthens the toughness of the segment to prevent breakage. |

| Co (Cobalt) | Cobalt powder strengthens the thermal stability of segment, making them ideal for use in high-temperature environments. It is more used in dry-cutting diamond tools. |

| Sn (Tin), Zn (Zinc) | Tin and zinc powders have a lower melting point and play an adhesive role. |

2. Powder Mixing

MX18/MXB18 Inverter Turbo Mixers For Diamond Segment Powders

Before cold pressing, the diamond powder needs to be put into the mixture and mixed for several hours to ensure even distribution.

3. Cold Pressing

Cold pressing is the process of transforming the mixing powder into segment layers. The process is completed by an automatic cold pressing machine. Once the correct pressure and other settings are configured, the machine will run automatically. Various moulds are used to create different shapes and sizes of segment layers, such as bars, arrows, buttons, and more.

VCP16/40A/80 Full Automatic Diamond Segments Cold Pressing Machine

For multi-layer cutting segments, there are 2 different types of layers: one is working layers with diamonds, and the other is transition layer without diamonds.

The diamond concentrations in each working layer are not all the same; the side layers have a higher diamond concentration than the middle layers. Thus, the middle layers are consumed faster than the side layers when cutting, resulting in a concave segment shape.

The concave segment shape provides a good cutting speed and minimizes blade deflection, producing a better cutting quality.

4. Die-Filling

Die-filling is the process to put the cold-pressed segment layers into the mould by order and fix them in the frame to wait for hot pressing. It's a completely manual job.

5. Hot Pressing

Hot pressing is one of the key factors in making diamond segments. In this step, the diamond segment layers are hot-pressed together to form a solid whole.

SM Series Diamond Segments Hot Pressing Machine

It is very important to set the correct temperature, pressure, and time. Different pressures and temperatures produce different qualities of diamond segments.

6. Mould Breaking

After hot pressing, we must cool the mould down and then remove the diamond segments from it. Identify and pick up the obviously unqualified segments. Tidy up the moulds for next use.

7. Deburring

The deburring process removes diamond segment burrs in order to prepare it for welding or packaging. It is done with an automatic deburring machine.

8. Quality Inspection

There are two main types of inspections for diamond segments: hardness and size. The hardness of the diamond segment is usually tested with Rockwell Hardness Tester (select samples for small-scale testing). The size can be inspected manually or with an Automatic Diamond Segments Sorting Machine.

9. Product Inbound

For inventory order, the diamond segments will be sent to the warehouse, waiting to be welded or packaged for sale. While for customer orders, the diamond segments will be sent to the packaging room directly for sale or to the welding place for producing diamond tools.

Sometimes, one production order is placed for both inventory purpose and customer orders, if the diamond segment in customer order is also what we what to stock.

Other Steps Remaining

10. Product Outbound ( Segment & Steel Core)

In this article, we will assume that the steel core is already in the warehouse, regardless of whether it is produced by us or purchased from other suppliers.

In the diamond tool industry, most manufacturers source their steel cores externally to save costs. This is because lots of diamond tools are customized. Unless you have large and stable sales of some diamond tools with uniform specifications, there is no need to produce the steel base (core) in-house.

On the contrary, for diamond tools manufacturers, the diamond segments must be made by themselves, because it's their key advantage. The steel base (core) can be copied easily. However, the diamond segment formulas are invisible and it's hard to copy.

11. Welding

There are 2 primary methods to fix segments onto a steel base (core): high-frequency welding and laser welding. High-frequency welding can be done semi-automatically or using a fully automatic machine, while laser welding requires a fully automatic laser welding machine.

The difference between high-frequency welding and laser welding

| Items | High-Frequency Welding | Laser Welding |

|---|---|---|

| Principle | Welding the segment and steel base together through solder, under high temperature. | Welding the diamond segment and steel base (core) directly under very high temperature |

| Solder | can be copper or silver; Copper solder welding is also called brazing and it has a higher welding strength than silver. However, there are cases where silver welding is necessary, like welding marble segments or PCDs. |

no need |

| Welding Base of Segment | no need | need special welding base |

| Requirement of Steel Core | normal steel base of 65Mn | special steel base of 30CrMo |

| Welding Strength | medium | high |

| Suitable Application | Cutting/Drilling: most natural stones. Grinding: stones, concrete, terrazo, and other materials |

Cutting/Drilling: concrete, reinforced concrete, asphalt, etc. |

| Representative Tools | granite diamond blades, marble diamond blades, floor grinding shoes, stone cor drill bits | concrete cutting balde, concrete core drill bits |

| Cost | lower | higher |

12. Quality Inspection

After welding, it is necessary to inspect the welding strength, especially in cutting tools such as diamond saw blade. The welding strength of small quantities of diamond blades can be tested manually, while for bulk orders, welding strength testing machines are available.

In addition, for diamond saw blades, there may be another process after welding - regulating tension. Because welding requires high temperature, the tension of the steel base before and after welding will change as a result of thermal expansion and cold shrinkage.

13. Painting

Painting is one of our OEM services. You can choose the unique colors you like, whether bright or matte, such as red, blue, green, purple, yellow, golden, etc., or provide the international color card numbers to us. However, You can also choose varnish to show off the beautiful metallic luster of the diamond tools instead of colorful paint, such as varnished diamond blades.

The painting has 3 main advantages or purposes:

- To Prevent The Steel Base From Oxidizing: For the tool itself, painting is to protect the steel base (core) and extend its lifespan.

- To Make The Color Suitable For Your Brand: Different companies have different cultures. They choose different colors as part of their culture, which can be seen from their logo.

- To Distinguish Different Specifications Of The Diamond Tools: For example, the floor grinding shoes usually use different colors to identify different hardness of bonds like soft, medium, hard, and others. This makes it simpler to locate the bonds you require.

One thing should be noted is that different colors have different effects on laser marking. In general, red is harder to print logo than other colors.

14. Sharpening (Opening)

Sharpening, also called opening, is the process to expose the diamond particles of the segment, making the diamond segments prepared to work. Be aware of the direction when sharpening. The sharpening direction is related to the rotation direction of the diamond tool.

MX18/MXB18 Inverter Turbo Mixers For Diamond Segment Powders

15. Laser Marking

Laser marking is the process of printing specifications, cautions, logos, etc. onto diamond tools with a laser marking (engraving) machine.

Laser Marking Machine

We print our logo on the diamond tools for end-users and distributors. For resellers or traders, It's one of our OEM services. Give us the information you want to print, we will create a sample and confirm it with you.

Common information printed on different diamond tools:

- Diamond Blade: name, diameter, segment size and number, direction, logo, features like silent, laser, arix.

- Diamond Cup Wheels: diameter, connection like M14, 22.23mm, etc.

- Concrete Grinding Shoes: diamond grits, bond type, logo.

- Bush Hammers: diameter, bush hammer roller numbers, logo.

- Diamond Core Drill Bits: diameter, segment size and number, connection like 5/8"-11, M14, etc.

16. Packaging

Packaging is an important thing we shouldn't ignore. It is also one of our OEM/ODM services and has 2 advantages:

- Protecting the product from damage during shipping.

- Sales-friendly packaging to grow your business.

We are here to discuss the OEM service for the minimum package. Although different diamond tools have different packing methods, you can still customize the packaging through 4 aspects:

- The information on the box: you can display your logo, company name, contact information, etc.

- The Packing Material - Like brown paper (as an outer package), EPE(used inside of the box), etc.

- The Quantity - How many pieces of diamond tools a box should have? It usually depends on your sales strategy.

- The Label - Stick a label with a product photo on every box to make it easy to recognize the tools outside.

Here is the packaging method of Onestop diamond cup wheels:

minimum packaging

minimum packaging

maximum pakcaging